Acqua Panna Plant

Barberino di Mugello, Florence

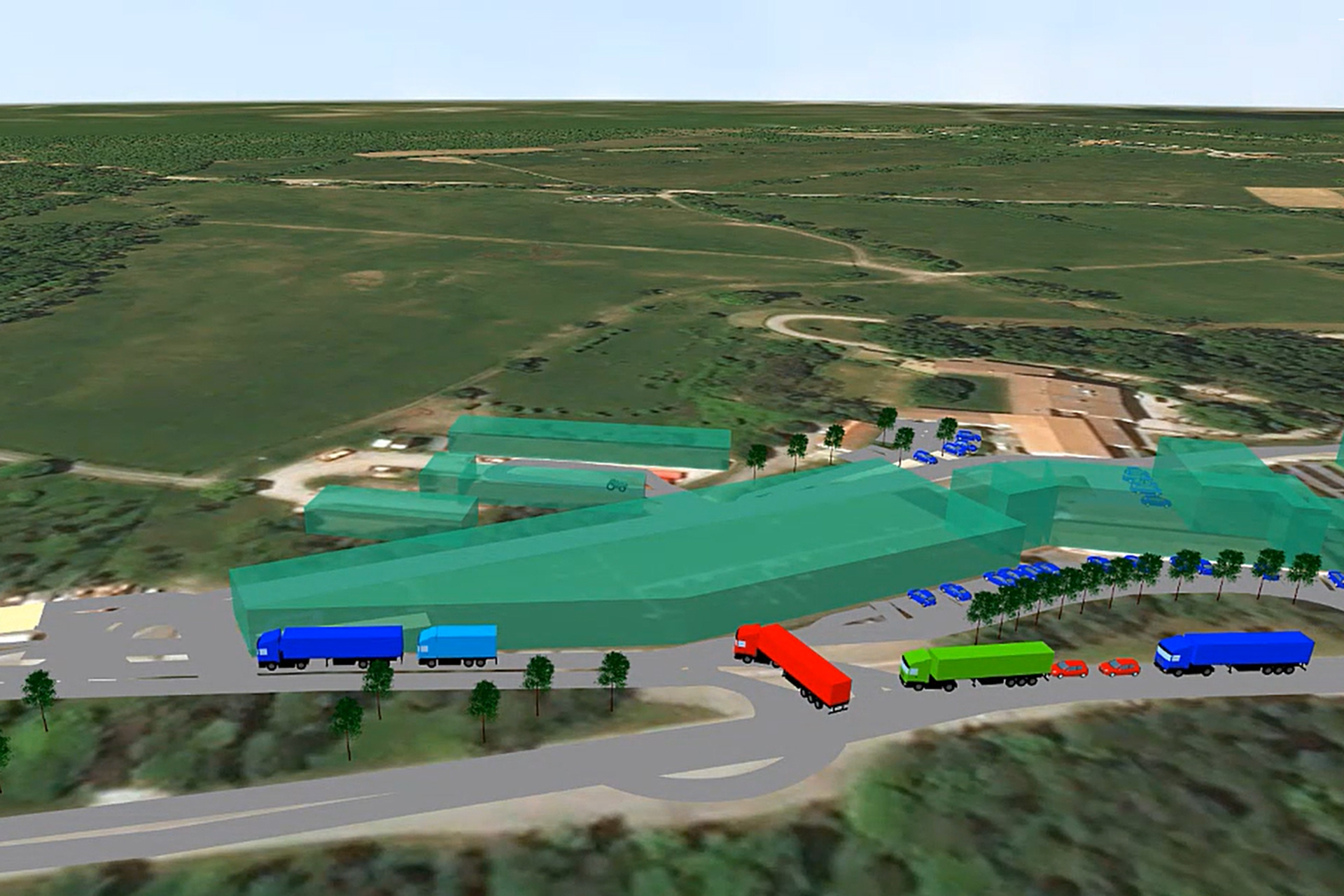

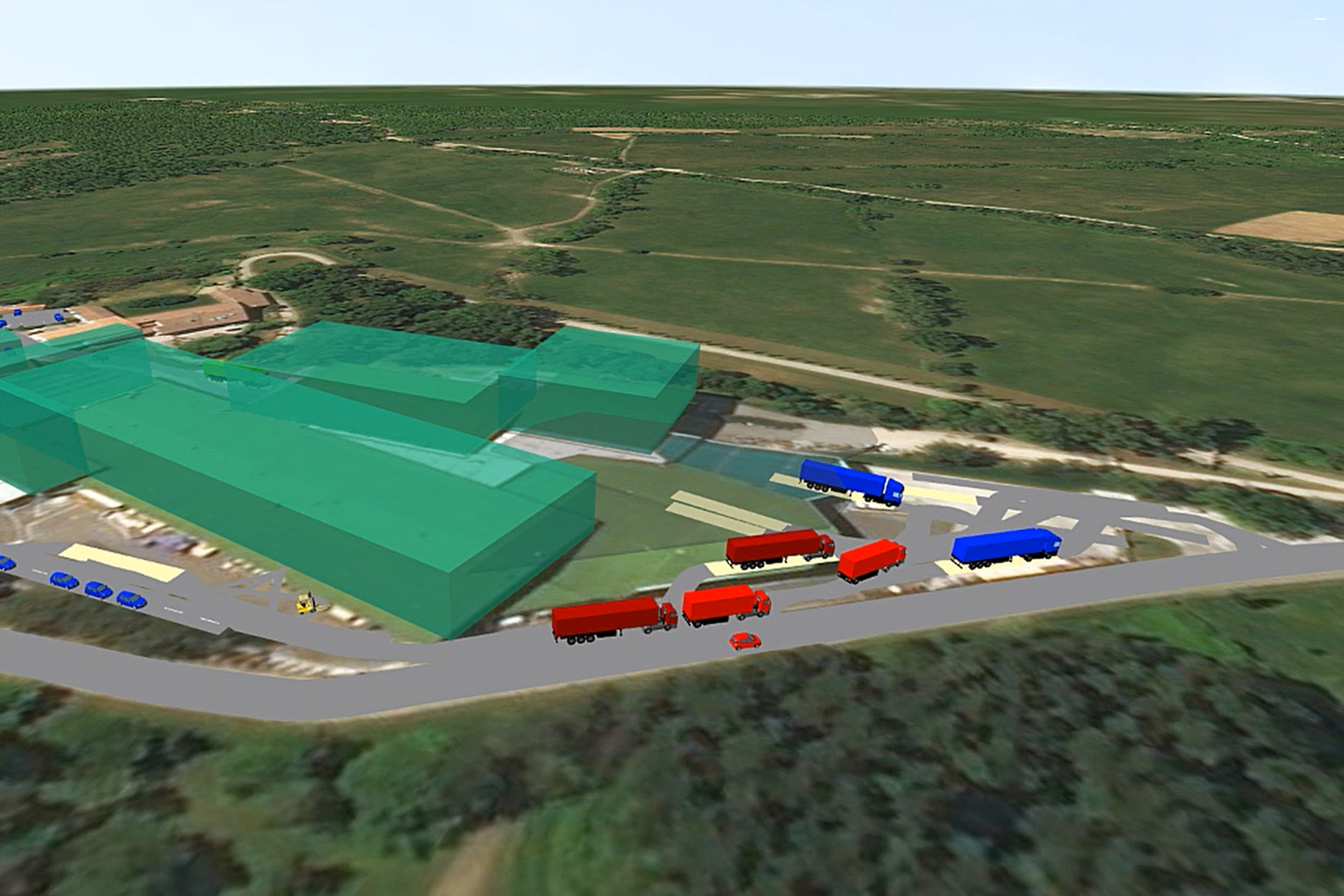

To support the refurbishment and expansion project of the Acqua Panna plant in Scarperia e San Piero, Barberino di Mugello, MIC-HUB conducted an in-depth study of the internal logistics and overall accessibility and created a microsimulation of heavy vehicle flows. The aim was to optimise accessibility and the management of flows inside and outside the production site.

The project was developed in several phases. In the beginning, MIC-HUB analysed the road hierarchy and vehicle accessibility to the site, as well as data on employee, supplier and logistics movements. This analysis identified possible overlaps during peak traffic hours and potential operational issues.Location

Barberino di Mugello, Florence

Client

Nestlè Waters

PROJECT HIGHLIGHTS

- Simulation model of logistics and site accessibility

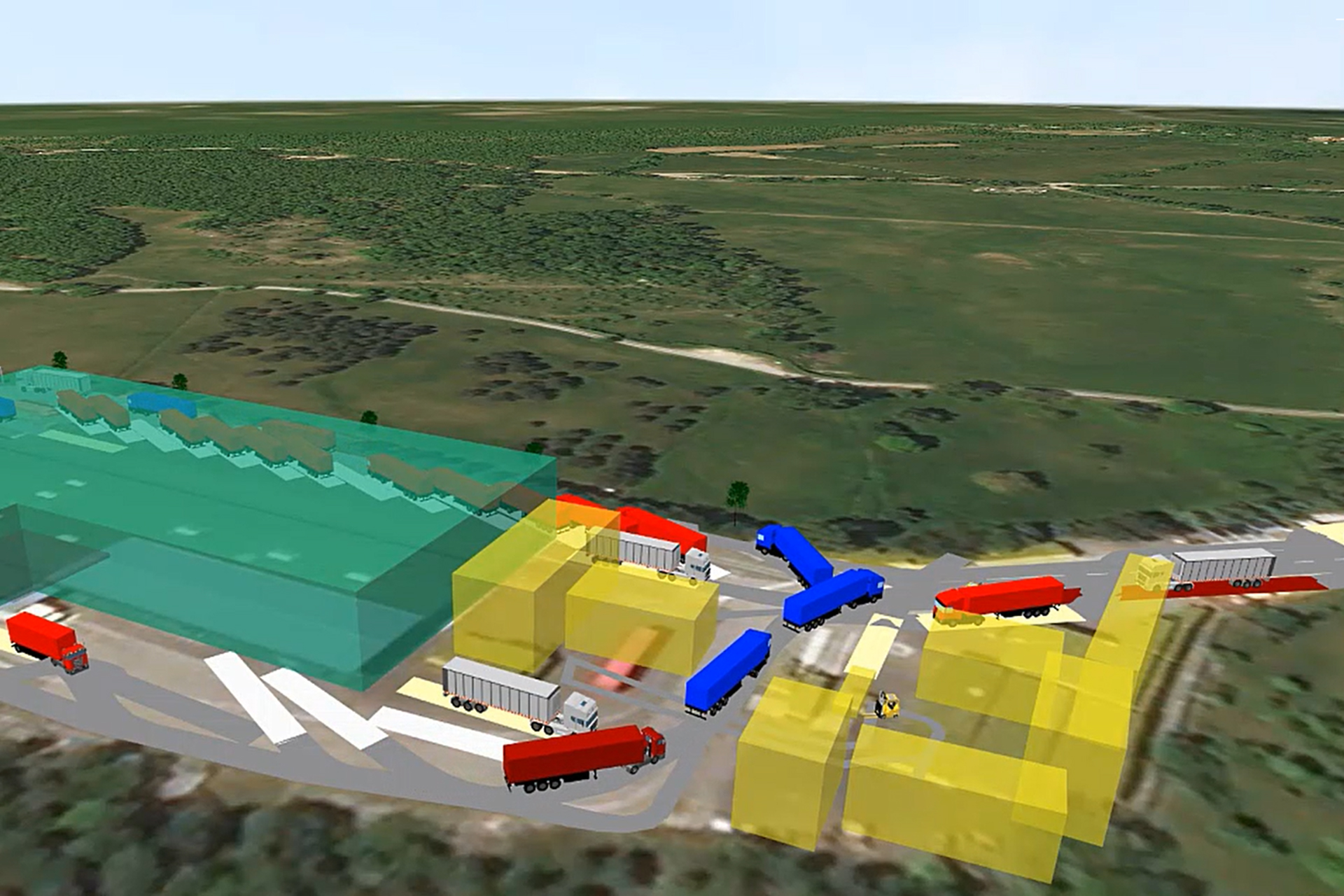

- Study of truck loading and unloading movements

Project gallery

Our contribution

A traffic survey was then conducted to determine the plant’s current flows, travel times, user types, and routes, forming the basis of the methodology.

From this data, a microsimulation model was developed to faithfully replicate all existing interactions on the internal and external network.

The model was used to assess the impact of the plant on the local road network, verify the functionality of access points, examine the internal circulation, and test the site’s capacity to accommodate the expected increase in production and related transport demand.

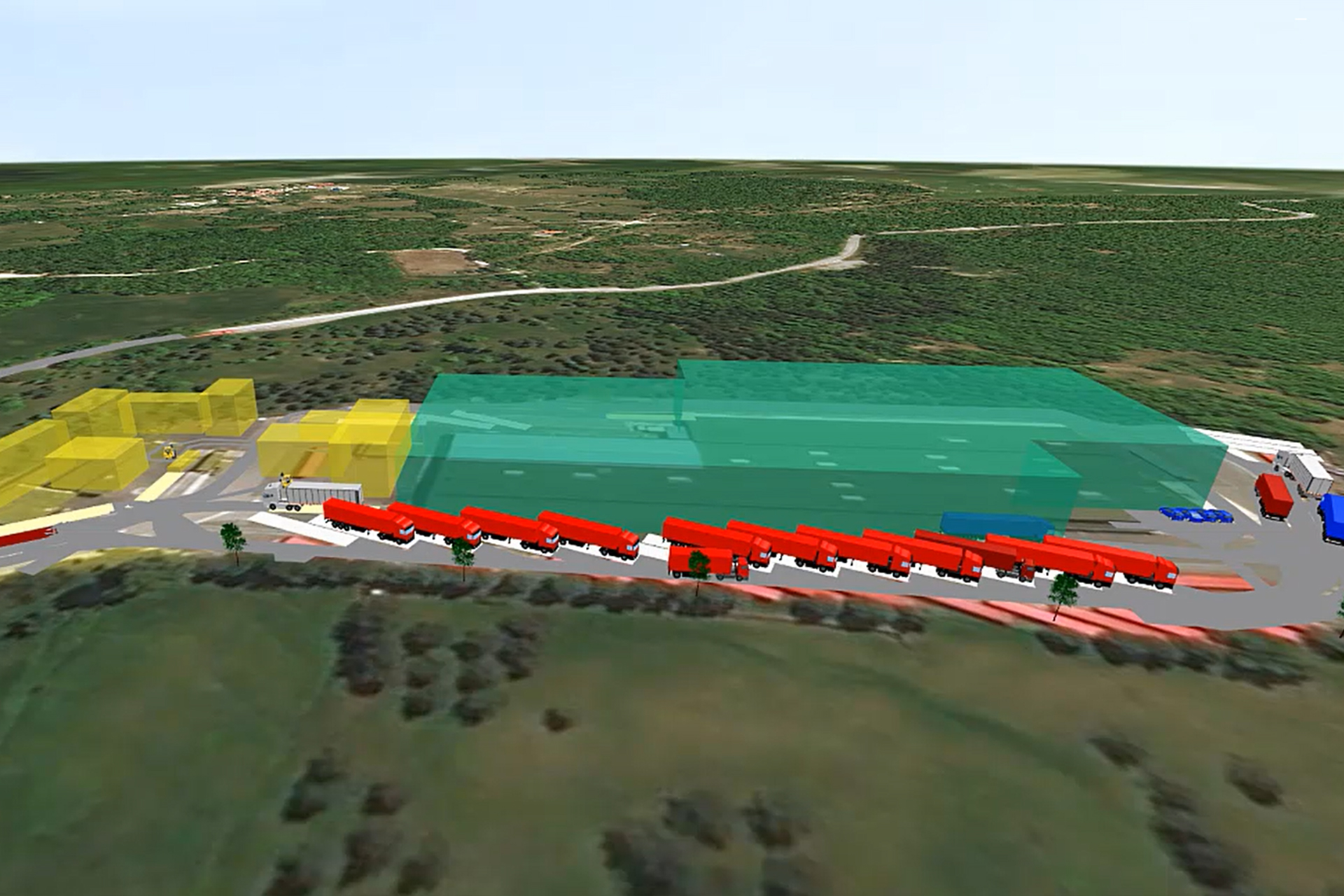

Our study simulated different growth scenarios, estimating thresholds beyond which plant performance could decrease, and identifying critical areas with the highest average delays.

Based on these results, MIC-HUB proposed targeted interventions to optimise internal logistics, plan strategic actions to improve efficiency, and to address the most critical issues identified by the client.