Acqua Vera Plant

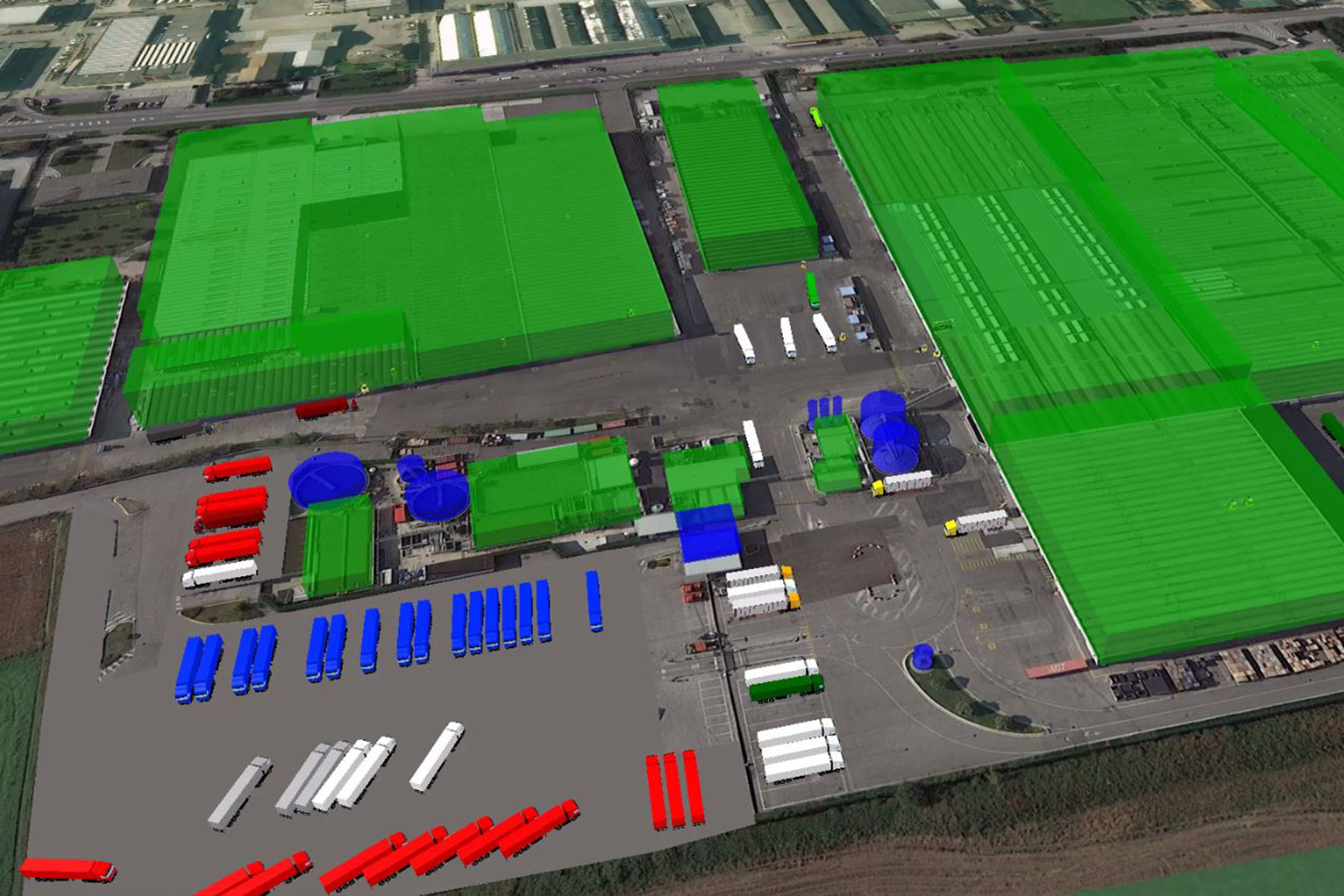

To support the future expansion of the Acqua Vera plant, MIC-HUB carried out a comprehensive analysis of accessibility, internal logistics, and traffic flows to assess how the facility could respond to increased production and related transport demand.

The study examined heavy vehicle and car circulation, loading/unloading areas, and parking spaces, integrating these elements into a simulation model capable of evaluating both current and future performance.Client

Nestlè Waters

PROJECT HIGHLIGHTS

- Simulation model of logistics and site accessibility

- Study of truck loading and unloading movements

Project gallery

Our contribution

The analysis investigated the plant’s existing configuration, calculating routes, manoeuvres, and dedicated areas for loading/unloading and parking.

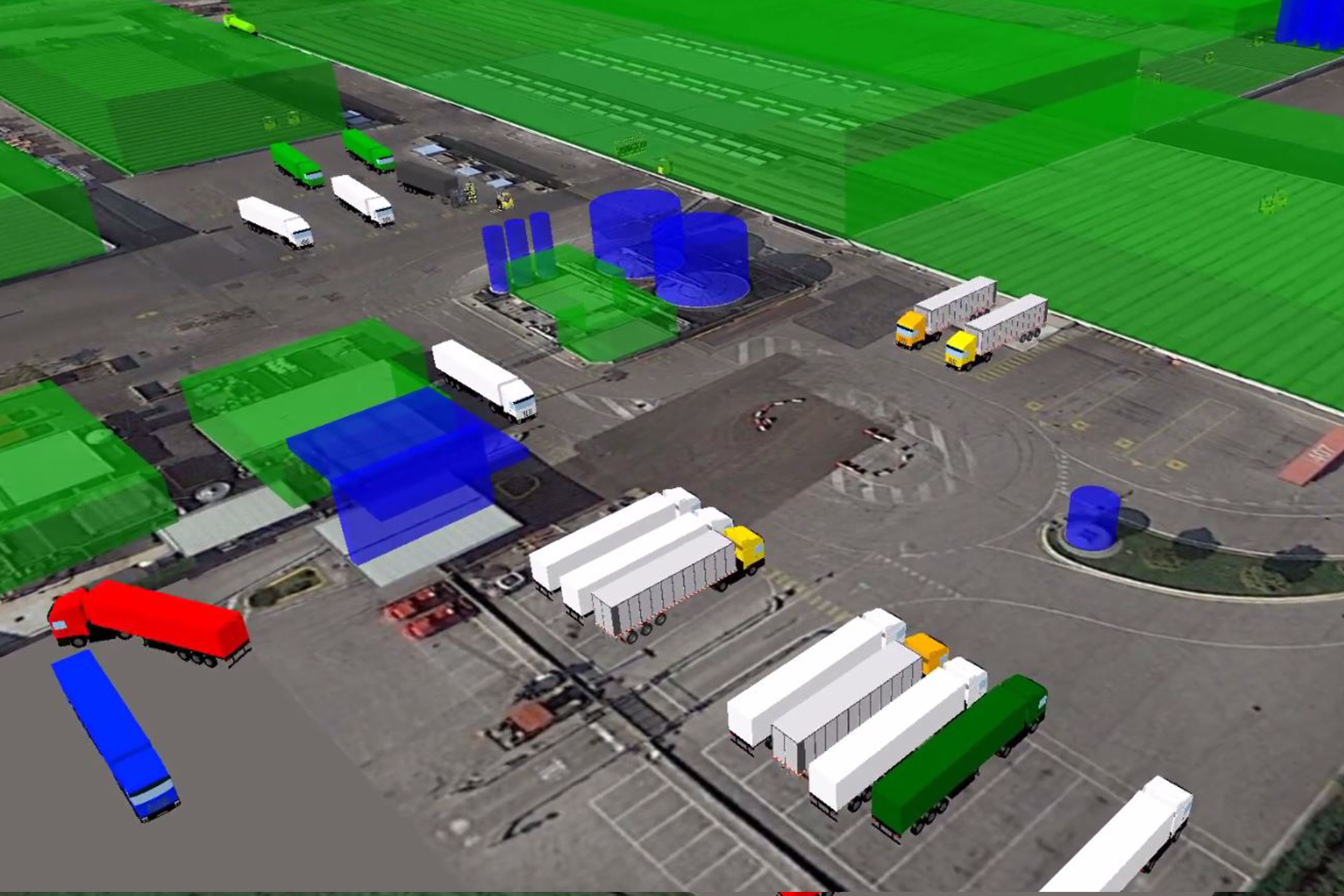

Our methodology was based on a traffic survey, recording flows, timings, user types, and travel patterns in order to build a microsimulation model, which accurately replicated real-life interactions.

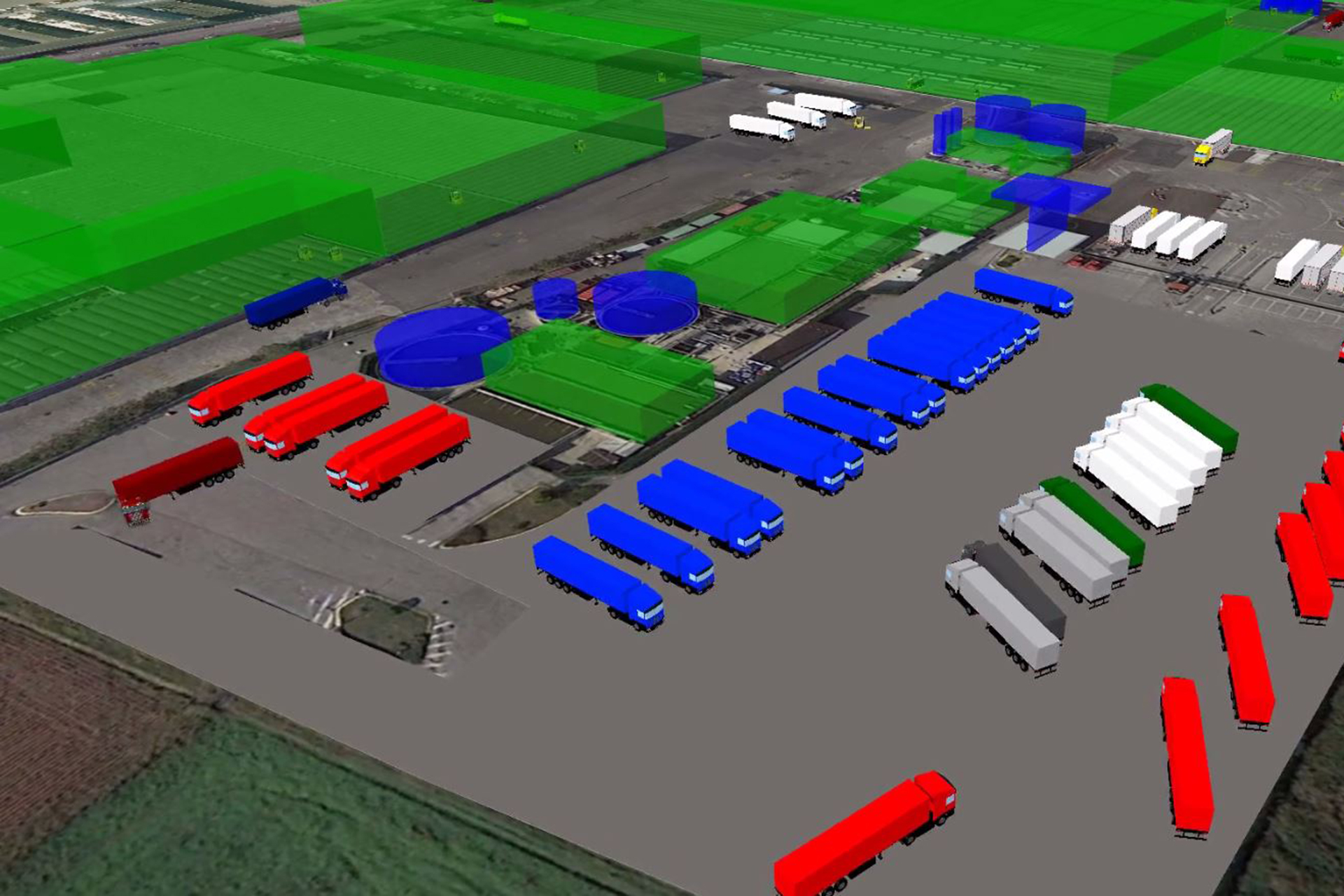

The model was then used to test different growth scenarios, assessing how rising production would impact internal logistics and external accessibility. The study identified thresholds beyond which the plant’s performance might decrease, as well as the areas with the highest delays.

Through this approach, MIC-HUB provided the client with targeted recommendations to plan logistics optimisation measures, ensuring operational efficiency even under increased production demand.